Posted by Alliance of Indian Wastepickers

Written by Anjanee Patel, Ambrosie, Jaspreet Singh, Indha Mahoor, Nalini Shekar, Karthik Natarajan, Vishwanath C and Xiao-Dong Liu.

Region Asia-Pacific

Country India

May 20, 2019

Written by Anjanee Patel, Ambrosie, Jaspreet Singh, Indha Mahoor, Nalini Shekar, Karthik Natarajan, Vishwanath C and Xiao-Dong Liu.. Waste Narratives. 05/14/2019

Bangalore based waste-pickers organization Hasiru Dala (India), along with researchers from an American university, undertook a research project to identify design flaws in existing dry waste collection centres. They came up with suggestion to better the collection centres. The current centres have been haphazardly planned, with infrastructure crumbling, pest problems, no ventilation or proper lightening, space constraints. The remedial prescription includes separate allocation of spaces for different types of waste, provision of better sanitation and north ward orientation of windows for light and ventilation, installation of bailing machine are the prominent ones.

Bengaluru is the second city in India, after Mumbai to have Dry Waste Collection Centres (DWCCs). The city civic body: Bruhat Bengaluru Mahanagara Pallike (Greater Bangalore Municipal Corporation-BBMP) started setting up DWCCs since 2012. The sanctioned number of DWCCs is 198. There are 166 DWCCs functioning in the city, with the capacity ranging from 0.5 tons a day to 4.5 tons a day. The DWCCs are operated with the participation of waste-pickers and informal waste collectors. 33 DWCCs are supported by Hasiru Dala (the ones operated by waste-pickers of which 14 are managed by women wastepickers) have a special order to engage in the bi-weekly collection of the dry waste directly. They were set up to provide decentralized dry waste aggregation and sorting facilities within the neighbourhood. The installation of DWCCs and inclusion of waste-pickers is a laudable initiative. The DWCCs receive the dry waste including high-value recyclables, low/no value materials like multi-layered plastic, rejects including bedding, shoes, cloth. The low-value waste collection has increased, around 82 percent of the total dry waste collected, after segregated door to door collection has been initiated by the Dry Waste Collection Operators. This has posed imposed important questions about the present design of DWCCs.

Bengaluru is the second city in India, after Mumbai to have Dry Waste Collection Centres (DWCCs). The city civic body: Bruhat Bengaluru Mahanagara Pallike (Greater Bangalore Municipal Corporation-BBMP) started setting up DWCCs since 2012. The sanctioned number of DWCCs is 198. There are 166 DWCCs functioning in the city, with the capacity ranging from 0.5 tons a day to 4.5 tons a day. The DWCCs are operated with the participation of waste-pickers and informal waste collectors. 33 DWCCs are supported by Hasiru Dala (the ones operated by waste-pickers of which 14 are managed by women wastepickers) have a special order to engage in the bi-weekly collection of the dry waste directly. They were set up to provide decentralized dry waste aggregation and sorting facilities within the neighbourhood. The installation of DWCCs and inclusion of waste-pickers is a laudable initiative. The DWCCs receive the dry waste including high-value recyclables, low/no value materials like multi-layered plastic, rejects including bedding, shoes, cloth. The low-value waste collection has increased, around 82 percent of the total dry waste collected, after segregated door to door collection has been initiated by the Dry Waste Collection Operators. This has posed imposed important questions about the present design of DWCCs.

The design of most of DWCCs has been developed based on the BBMP circular issued on 15.02.2013 and based on an older understanding of Dry Waste management. In order to systematically understand the gaps and challenges, early this year (Feb-March 2019), a group of four students from University of Washington (GCIL program), with the staff of Hasiru Dala conducted an exhaustive probe on the condition of 16 DWCCs, they documented the centres for their operational issues, structural condition and capacity expected vs fulfilled. The survey was conducted by Anjanee Patel (M.Sc.Environmental Engineering.), Ambrosie Longrie (B.Sc. Environmental Engineering.) and Xiao-Dong Liu (Civil Engineering), and Jaspreet Singh, (Medical Anthropology). The Study was coordinated by Indha Mahoor (Project Manager) and Karthik Natarajan (Architect and Housing Project Coordinator) along with on-field associates of Hasiru Dala. The survey looked into the design, composition of waste, additionally considered the number of people working there and their everyday lives and their role in the solid waste management of the city. Most of the DWCCs are haphazardly installed four-walled structures with tin or cement roof. These DWCCs lie in structural disrepair, due to functioning at over capacity

Common design challenges in the DWCCs outlined below:

- Lighting and ventilation: Owing to the makeshift nature of the structures, they are poorly lit and ventilated, making it tough and unhealthy for the people working inside for hours together. Many DWCCs depend on electricity for both light and ventilation, which owing to the frequent power cuts end up being unreliable.

- Wiring left open: Due to makeshift cabling, poor maintenance and repair, and the heat generated from the tin roofs, the electrical wires end up becoming a fire hazard.

- Water and sanitation: In most of the DWCCs surveyed, there was less to no attention paid on toilets or plumbing. Most facilities simply lacked toilets, and the ones that had toilets, the plumbing wasn’t functioning or no connection with the sewage lines.

- Cleanliness: When households don’t segregate their waste and send, the mixed and reject waste ends up reaching the DWCCs and lies there until it is picked up or sent away. There is no proper stocking of reject waste.

- Construction issues: Improper construction know-how and make-shift buildings mean structurally un-sound buildings, add to that the age and lack of repair/upgrades to the DWCCs a lot of them are falling apart.

In many of the DWCCs, one can notice parts of the floors and even the walls have started to cave in due to ill-considered structural design and usage of substandard materials to build these DWCCs quick and cheap. The foundations in many have been badly damaged from rodents digging underneath. And in one case the DWCC is built over a drain, which could collapse at any time. - Roof leakage: On the rainy days, leaky roofs and seepage through wall cracks and windows lead to damage of high-value recyclables like newspapers, magazines, and cardboard boxes. Temporary fixes each year stresses the existing structure further leading to further damage. This costs money for the operators and no provision of a long-term solution.

- Property Damage: The land outside the building, where the loading and unloading are done, was surfaced only in few DWCCs, and over the years even those have developed cracks and broken under the load of the moving goods. This has led to uneven settling of the land and unsafe loading/unloading. The water logging that happens in these fissures also leads to poor working conditions.

- Pests, Rodents, and animals: Many DWCCs have rats and insects running through the cracks in the floors and walls. In a few DWCCs where the compound wall has been damaged over time, there have been cases of dog-bites from the dogs squatting on the DWCC premises. Snakes have also been observed on rainy days.

- Working conditions: Tin sheds heat up during the day, and in unventilated spaces, they create difficult working conditions. Rainy days are especially hard to work in because recyclables get damp and dirty and the paper ends up losing value. Mattresses that don’t move out of these DWCCs end up soaking in water and getting mouldy, making their disposal challenging.

- Space Constraints: A lot of DWCCs have been allotted smaller space than the capacity requires. Since from door-to-door collection of dry waste, the majority of the waste that comes is non-recyclables and rejects, space ends up being overrun with bags of multi-layered plastics, mattresses.

Remedial design suggestions to better DWCCs

Hasiru Dala has experimented with few design changes in the municipal ward 44, Marapana Palya which has shown visible results in both operations and in the lives of those working at the centre for the last three years.

Based on the observations from the study, a list of considerations is shared below, which will help build more future- ready DWCCs. They take into consideration, growth, working conditions, types of waste received (beyond recyclables) and operational necessities.

1. The flow of waste through the DWCCs

- Unsorted waste to be stored at the entrance.

- Plastic should always be at the end;

- Paper can be stored in the front which can be saved in case of fire.

- No electrical wires in the stocking area of plastics and other inflammable materials that need to be stored in DWCC.

- A conveyor belt is essential to improve the productivity of the workers and provide ergonomically appropriate work condition.

- The hopper for conveyer belt should be below the floor level, it makes it easy for the workers to unbag the materials for conveyor belt

- Frequently saleable materials should be store closer to the door,

- Rarely sold items (like metal) which are generally low volume materials items move to the upper or mezzanine floor.

- Minor electronic waste should go on upper or mezzanine floor. It is low in weight and takes a while to collect and transport.

- Space for baling (space around baling machine to walk and move around)

- Non-recyclables storage typically needs a large space.

- Availability of reject waste bins that can be closed and difficult for rodents to reach.

2. Facilities to be provided in an optimally designed facility:

- Office space and changing rooms with lockers for the workers.

- Toilets (overhead water talk for drinking and sanitation use) with a sanitation pipe connection.

- Appropriate space for a fire extinguisher.

- Appropriate space for weighing machine

- Record keeping (Computer + Storage)

- Display of boards that depict process, types of waste being sorted and other functioning’.

- Display rate card of material prices.

Things to consider in the structure:

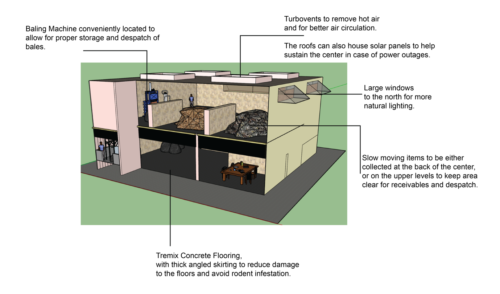

- Radiant heat both inside and outside: To save time during construction, a lot of these DWCCs were built with tin or cement sheet sheds. The temperatures inside them during high sun times rises to unworkable conditions. To prevent this, wherever suitable, insulating materials (for example Thermocol) should be used. Large windows should be on the north side, and openings to facilitate cross ventilation should be provided.

- Soil tests: Prior to construction soil tests to be made mandatory and the structural design must take into account seepage in the land once waste starts to be collected in the DWCCs.

We also must design these DWCCs as high moving load areas and the driveways must account for heavy loads in peak hours. - High ceiling The DWCCs with enough volume will help with working conditions during the summer months. It will allow for expansion of the centres capacity once the current structure is performing at optimum levels. The upper deck can be used as office space, storage of slow-moving light weight items.

- Roof lighting: The transparent panels need to be used to help light or use turbo vents to help ventilate buildings without the need for power. This will help save costs and minimise health issues (especially respiratory issues) from working in dark and closed off conditions.

- Robust materials: One of the major issues with the DWCCs surveyed was the condition of the door openings and windows. Over time, with use and neglect, they are either permanently closed off or permanently open, the glass or infill panels are broken or cracked, and they provide no protection from the elements. The material for the doors and windows should be robust, which will survive harsh usage in high traffic areas and will be sufficiently lightweight to be used by anyone at the DWCCs.

- Ferrocement door and window shutters: These will go a long way in this regard. They are hardy and waterproof enough to withstand any use and with the right detailing can be used for years without falling apart, unlike their metal or wood counterparts.

- Tremix flooring Internally (VDF): This is an industrial monolithic flooring, designed and used specifically in high traffic areas where tiles and other flooring tends to crack. This will also help fight the settlement of the structure in case of wet or loose soil. It is higher in terms of set-up costs, in the long term, it will pay out in reduced repair costs through the life span of the building.

- Skirting to prevent Rodent infestation from wall cracks: In order to avoid rodent entering from corners of the building (as it is very easy to make holes in the building), the skirting should be at 45% and the gap can be filled with broken ceramic or glass pieces.

- Appropriate bin for tube-lights

- Annual audit: The condition of these DWCCs should be investigated once a year, to fix problems early on. The facilities that the people at the centres use need more frequent checks and repairs, but the overall space can be checked once a year and major repairs can be avoided.

Value Added Measures:

- CCTV camera.

- Security Room like a fishing bowl style that will promote easy supervision

- Garden to keep the smells at check. Specific spaces of planting flowers that will enhance fragrance ( For example Parijat / Nyctanthes, Jasmines, Tube Roses, Raat Ki Rani / Cestrum, Sweet pea, Champa, Kewda/ Ketaki, Gardenia/ Cape Jasmine, Sweet Alyssum, is recommended).

- Mural outside that depicts the functioning of the centre and the people who run it.

- Small composting unit to discard wet waste that has come with the dry waste. A storage drum for dry leaves.

- Pest control measures- regular pest/rodent control either chemical and or electronic device.

- Rainwater harvesting for surface runoff.

- Solar panel for light, water pump and simple baler.

- Proper sanitary bin that has been collected in dry waste

This research has been made by Anjanee Patel, Ambrosie, Jaspreet Singh, Indha Mahoor, Nalini Shekar, Karthik Natarajan, Vishwanath C and Xiao-Dong Liu.

Tweet